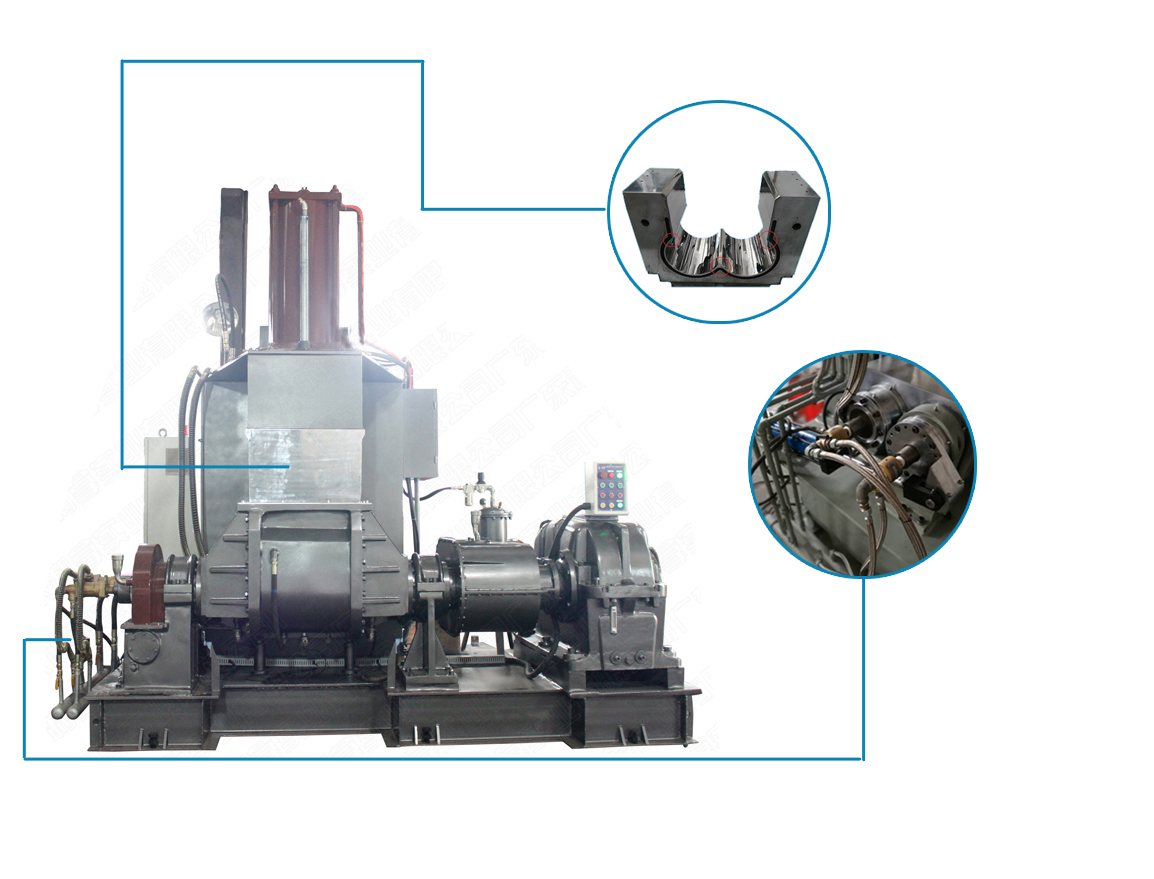

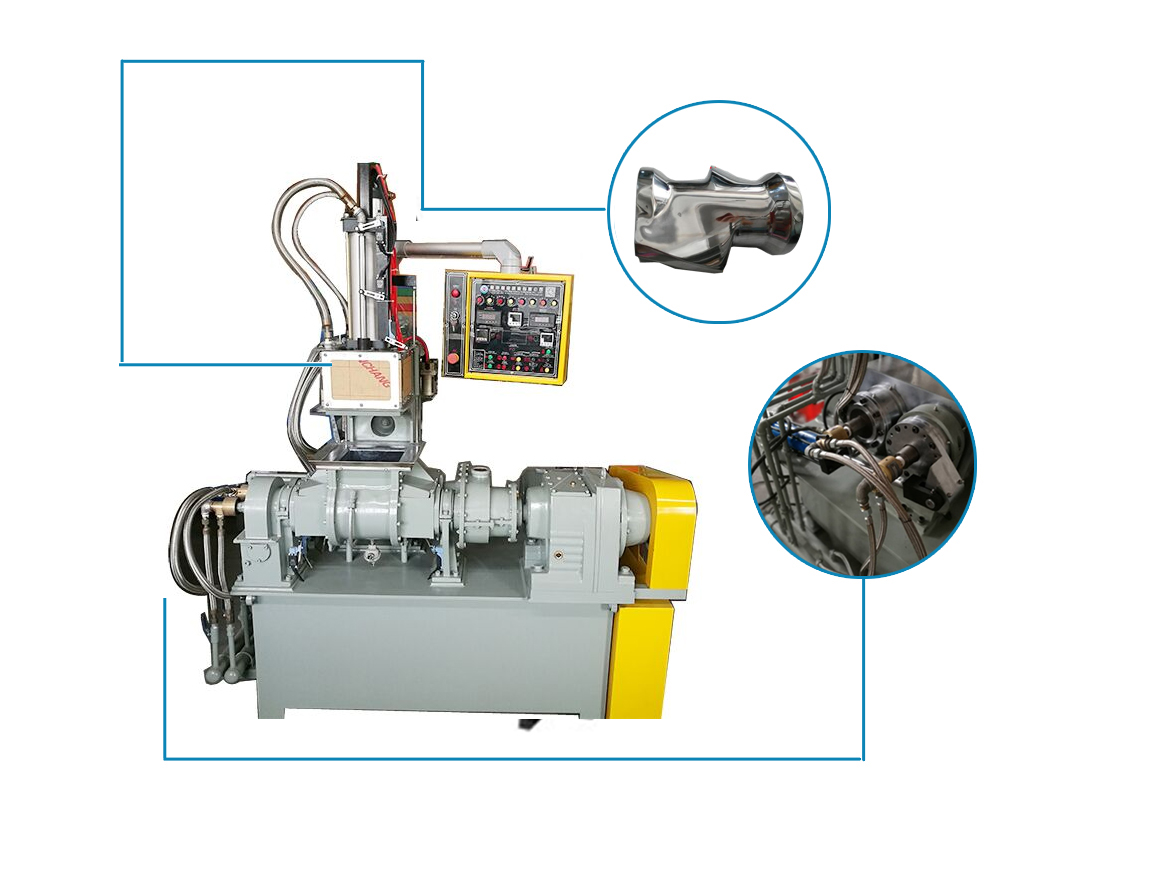

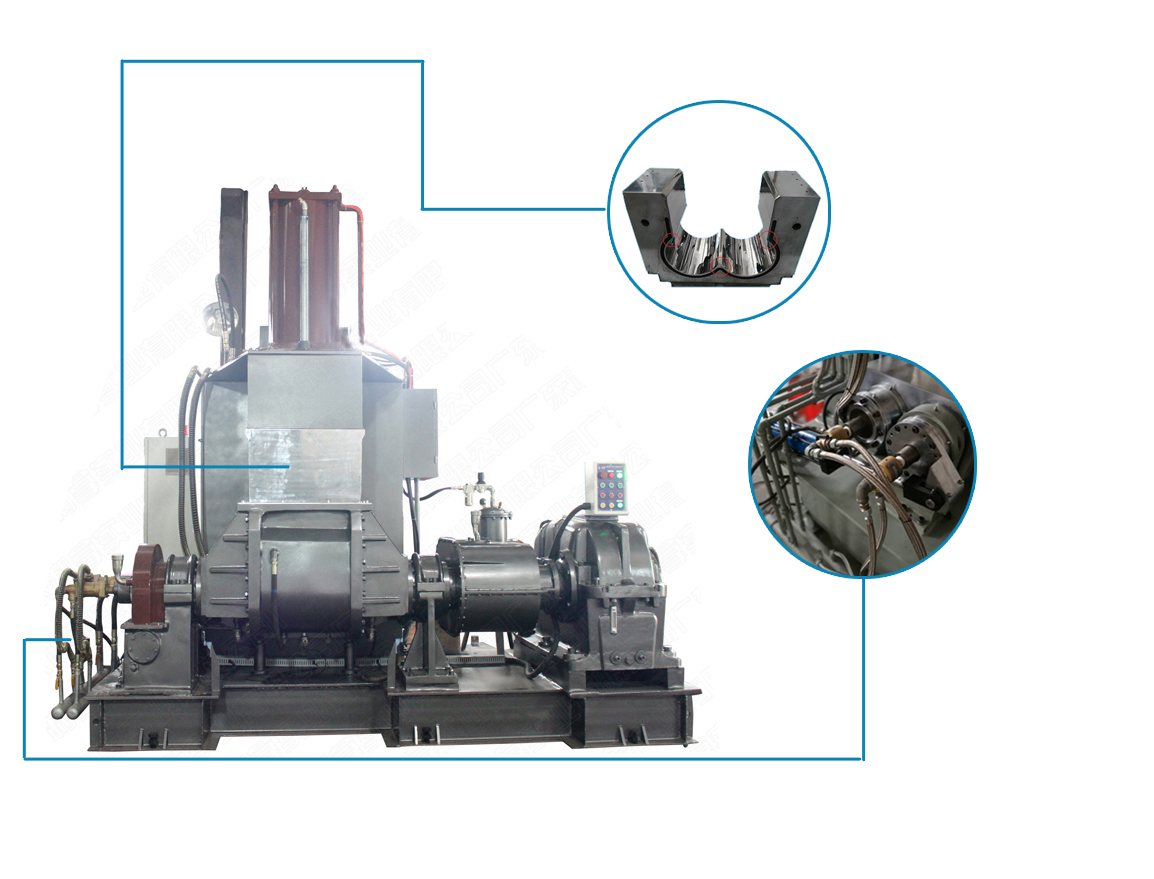

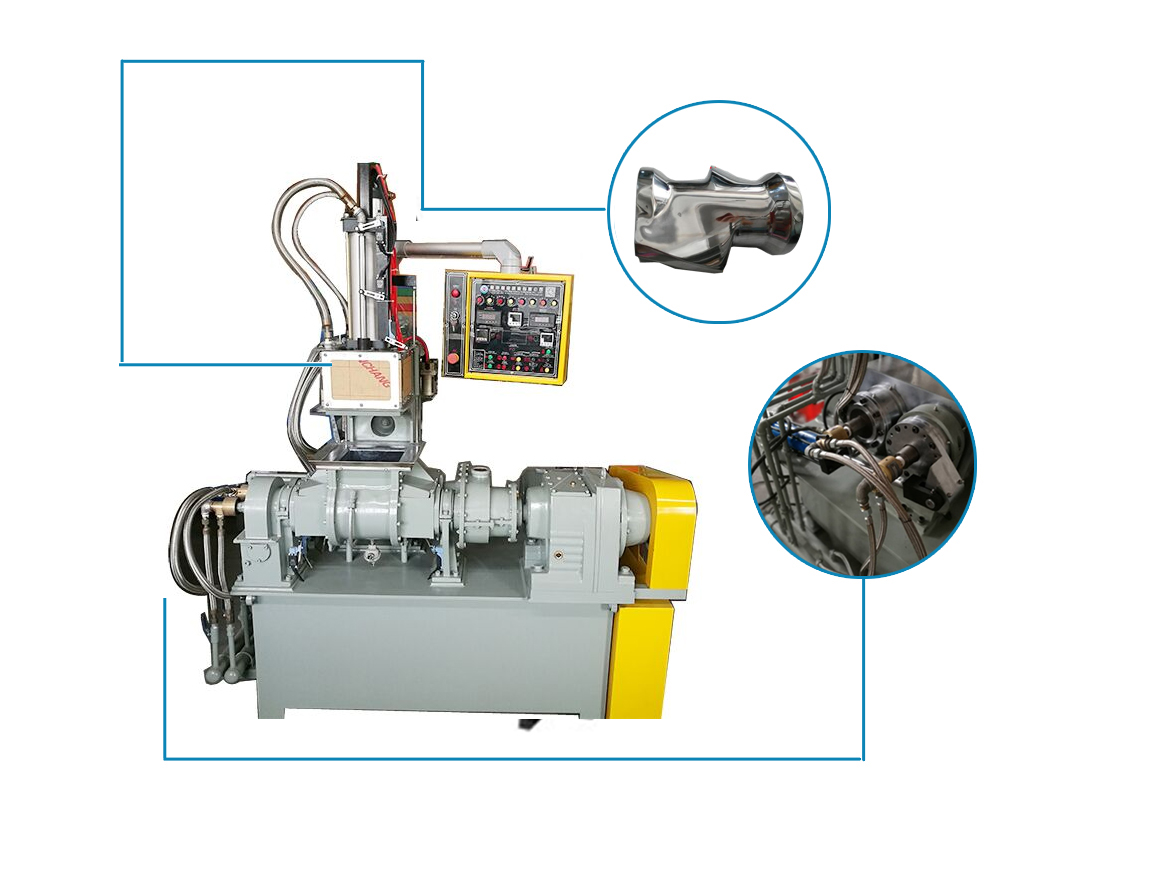

LINA Pressurized Dispersion Kneader

LINA high pressurized dispersion kneader is used for a variety of materials including high filled rubber, plastic and rubber plastic compounds. LINA dispersion kneader's mixing chamber is specifically designed for materials that need high pressure and enclosed mixing environment. Materials are kneaded intensively by a "M" type pressure lid, so the polymers are bonded with fillers more effectively and improving the filling ratio.

Working principle of LINA's "M-W" type mixing chamber

M-W pressing and molding mixing chamber of LN dispersion kneader is applied to ensure good abrasion resistance and even mixture of materials and optimized change of physical nature. 2-turning design is applied for leakage-proof device to largely enhance leakage proof performance, and the built-in dust collector allows for convenient and quick collection of dust.

The mixing chamber is made of advanced special steel, with surface treated with abrasion resistant steel, coated with hard chromium to provided excellent abrasion resistance and its service life 1-2 times longer than traditional dispersion Internal Mixer. The mixing chamber is divided into tipping type and lifting type. Dry mechanical shaft seal is used to ensure easy maintenance and environment protection.

Specifications of LINA pressurized dispersion kneader

| LN Dispersion Kneader | Type | Size | Dimension (mm) | Weight (kg) |

| LN-LAB TEST (LT) kneader | 0.5 | 1600*900*1900 | 800 |

| 1 | 1600*900*1900 | 800 |

| 2 | 1600*900*2000 | 900 |

| 3 | 1600*900*2100 | 900 |

| 5 | 1900*1000*2100 | 1200 |

| 10 | 2200*1350*2150 | 2500 |

| LN-Mass Production | 15 | 2200*1350*2150 | 4000 |

| 20 | 2500*1450*2450 | 3800 |

| 25 | 2500*1500*2500 | 4500 |

| 35 | 3200*1900*3000 | 6500 |

| 55 | 3300*2000*3100 | 7800 |

| 75 | 3800*2300*3200 | 10800 |

| 110 | 4100*2300*3400 | 16500 |